Table of Contents

FramingNailersGuide is reader-supported. If you buy an item through the links on this site, we may earn a small commission at no extra cost to you. Learn more

Last Updated on April 16, 2024 by John Patterson

Modern woodworking, metalworking, or machining had evolved a lot. But after massive turns and twists in the machinery, some tools had been able to keep their appeal still up. And chisel is one of those very few names.

In this post, we’ve done a thorough discussion of different types of chisels and their uses, along with essential tips.

Let’s get, set, and go-

Chisel Definition/Meaning: Definition Chiseled

Chisels are special kinds of cutting tools that widely used to sharpen, shape, re-shape and carve hard materials like metal, stone, or wood. It has a sharp cutting edge through which it’s able to provide a wide range of sizes and shapes to the workpiece. Let’s know chiseling wood properly.

Chisel itself is a broad terminology, where we can divide chisels into carver, gouges, V-tools, and basic chisels. Based on the cutting edge, blade structure and handle type, each of them has its values to the users.

List of Different Types of Chisels and Their Uses in 2024

Here is the list of updated and detailed guides to types of chisel.

List includes-

- Masonry Chisel Types

- Stone Chisel Types

- Types of Wood Chisel

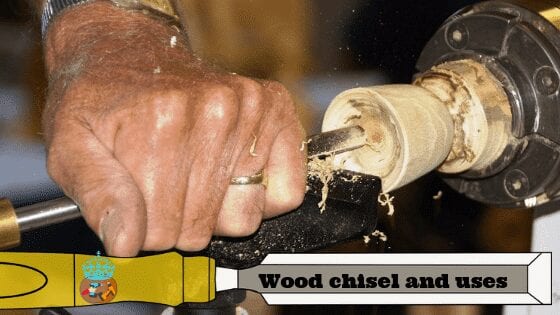

#1. Wood chisels

Wood chisels or wooden chisels generally defined to have a wooden handle and a metal blade. Although both the handle and blade have many variations in sizes, uses, workloads, and applications.

Let’s take an example. For working with larger workpieces at outdoor worksites like construction, you need to have a longer, more full blade and a comfy, long handle.

On the other hand, if you have to work with a smaller scenario like the hinges of a door, you need more modest versions of wood chisels.

These two were just random cases. Based on the demand of the situation, there can be 100s of variations of wood chisels. Let’s have a look at the quality wood chisels brands in 2024.

Read this latest Narex Chisels Reviews and Buyer’s Guide.

Wood Chisel Uses

- Almost any area where you need to sharpen, size, taper, or clean wooden workpieces.

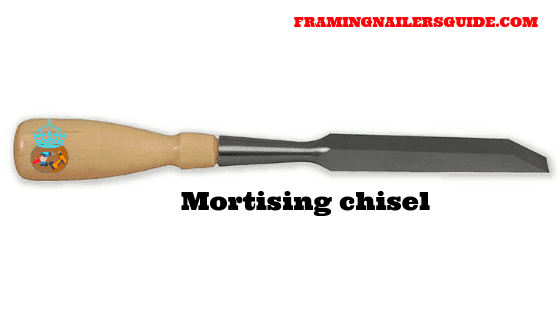

#2. Mortising chisels

Mortising chisels are quite heavy thick and ample in size. The bolsters entirely bogged in size and made of beech or oak wood. One of the most excellent sides of them is, they are pretty easy to handle and operate.

To work with almost all of your mortises, one mortising chisel would be enough. The ideal size is likely to be ¼” or ⅜.” Based on the glue surface or width of the Tenon, the strength of the mortise can vary.

Mortising Chisel Uses

- In most cases, the mortising chisel used to size mortises of various strengths and widths.

#3. Power chisels

Power chisels are not like most of the chisels we’re talking about in this list. Because, unlike anyone else, they powered with a grinder motor.

This carving tool does the same job that any traditional hammer or chisel would do. Just the way of working is faster and more comfortable with the motor.

To guide the tool, you have to give hands. And before that, you need to choose the blade type that you want to equip it with.

Talking about the blade, there are no fixed blades in this kind of chisel. You can choose the right one from a set of blades that come with the box.

Power Chisel Uses

- To deal with heavy woodworks where hardwoods are supposed to be processed.

#4. Masonry chisels

We introduced many chisels that work with wood and wooden jobs. But Masonry chisels are exceptions, and they work with stones, bricks, and even harder materials.

The way of working with a masonry chisel is to tap the blade on the stone/brick surface gently and to create scores. Gentle taps on the surface let the stone snap off as the line is made done.

The uses of masonry chisel come to be widespread. As they are not designed to work with woods only, you can deal with bricks, concrete blocks, soft stones, and any works of similar hardship.

Masonry Chisel Uses

- To work and design with masonries such as bricks or concrete blocks.

- To deal with soft stone with the teeth provided with masonry chisels.

#5. Concrete chisels

A concrete chisel is a particular type of chisel that comes with a pointy tip and used only to work with concrete surfaces. Having a sharp tip instead of a sharp edge is perfect for the job, as you have to cut through the concrete instead of shaping or sharpening it.

Another task that we can do with a concrete chisel is to demolish concrete surfaces. It’s a massive duty task that may need a hammer drill or a jackhammer.

Also, when you have to remove a small portion of concrete from a more massive object, that’s also the time when we go for concrete chisels.

Concrete Chisel Uses

- To cut through concrete surfaces.

- To demolish concrete projects.

- To remove concrete material from more significant objects/jobs.

#6. Lathe chisels

Lathe machine is a complicated and complex machine, and many kinds of operations are possible to do with it. Some of such actions are to provide V-cuts, turn beads, turn large coves, pummel cuts to workpieces, lathe chisels come in use.

Lathe chisels are available in many sizes ranging from 2mm to 38mm of blade width. For general uses, most workers prefer to start with 25mm of width.

Unlike many of the other chisel types, lathe chisels are easy to maintain, even for beginners. Therefore, it’s one of the chisels with the least convenience needed.

Lathe Chisel Uses

- To provide V-cut, plummet cut.

- To provide a plane and turn beads.

- To create shallow and long caves.

- To assist lathe workers in processing workpieces.

#7. Cold chisel tool

For handymen who work with metals, there are very few tools available apart from saws or shears. And one such rare but helpful kind of tool is cold chisels, which are massively used to work with heavy metals.

One excellent property of cold chisels is- they can cut any material that is softer than it. So, they widely used in repair works such as cutting off rivets, slicing through rusted nuts, etc.

Cold chisels were in use massively before the invention of machining tools. But they have their appeal to metal-workers even today.

Cold Chisel Uses

- To cut any metals that is softer than the material of cold chisel itself.

- To provide a plane and turn beads.

- Removing bolts and nuts from a rusted condition.

#8. Stone chisels

You may have seen sculpture artists use some small-size chisels to bring out a sculpture from stone pieces, right? These kinds of chisel are what we call stone chisel. And it has many other applications apart from the statue only.

To cut and remove stone material quickly, hardened steel is what we use to make these chisels. In the case of dealing with harder stones like granite or carbide, we need a more powerful chisel, like tipped chisels.

Stone Chisel Uses

- To assist in removing, shaping stone material from stone workpieces.

- To work with even harder stones like granite etc.

#9. Paring chisels

Chisels are sometimes quite significantly used for finishing jobs, and paring chisels are one of the most excellent examples of that. They are long, thin, and beveled sidewise. The sidewise bevel helps to smoothen up any surface.

Also, the cutting edge of them can be used to provide cuts of up to 15 degrees. The cutting edge sharpened accordingly. For pattern makers, these chisels are very delightful to use.

Uses of Paring Chisel

- To provide smooth cuts of an angle of up to 15 degrees.

- For smoothing and finishing works.

#10. Cape chisels

Cape chisels aren’t the kind of chisels that we have to use often. They are a variation of cold chisels that have a long taper on the top of the blade. Also, the bottom side of the cape chisels is narrow-edged.

Like cold chisels, they can work with any metals that are softer than the material of the cape chisel itself. So, when it comes to creating grooves and tiny details on a string metal, cape chisels come to use.

The narrowed-down tip helps to work in detail.

Cape Chisel Uses

- To cut keyways on metal bodies.

- To cut horizontal grooves on metal bodies.

#11. Framing chisels

We have gone through the description of firmer chisels earlier. And the farming chisels are just the thicker-bladed versions of them. Starting from heavy woodworks to outdoor applications such as timber framing or boat building, they massively found.

Framing chisels are extensive in size, long enough and the blade is quite thick. So, the cutting edge that they have is quite sufficient (25 to 30 degrees).

Framing chisels are both available at the straight edge and beveled edge version. And as they have to withstand repeated strikes, they also come with additional features such as sockets and capped handles.

Framing Chisel Uses

- Heavy-weight applications such as boat building or timber framing.

#12. Carpenter’s chisels

No need to mention that carpenters have to deal with a handful of tools, and a chisel is supposed to be one of them.

Carpenter chisel isn’t a particular type of tool, as we know. Carpenters have to use many of them including mortise, gouge, carving, paring chisel, and so on.

For different jobs like tapering, machining, sharpening, cleaning, and so on, carpenters modify the tips of each of these chisels.

Carpenter’s Chisel Uses

- To help carpenters to the machine, taper, sharper, or clean workpieces.

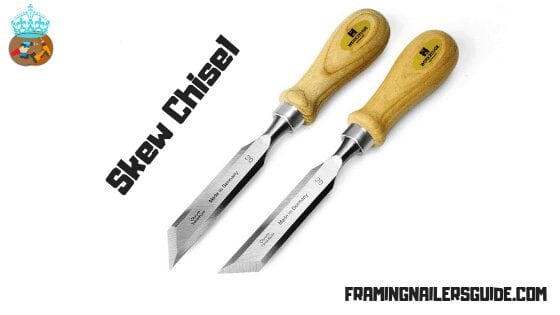

#13. Skew chisels

Skew chisels are one of the essential tools that woodworkers have to use on a regular basis. It’s a long and flat bevel-edged chisel that has an angled tip as well.

The long point that the chisel edge has is called the toe. And the shortest end of the cutting edge is called the heel.

However, for a newbie woodworker, working with the toe and heel would be tough. At least, we have seen many real woodturners struggle with it because it needs proper pressing and digging to do it in an appropriate fashion.

Skew Chisel Uses

- Smoothing and beading.

- Tapering and creating V-cuts.

#14. Butt chisels

The name of the butt chisel quite expresses the reason it used for. To work with butts and hinges, you may need to use a butt chisel while installing.

To recognize them, we need to look at the unusual shortness of them in size. We are comparing it to the bench or firmer chisels just with shorter blades to work with.

And nonetheless, carpenters have found their uses with this one.

Butt Chisel Uses

- For woodworking, especially for installing butts and hinges.

#15. Brick chisels

As we all know, chisels are not only to sharpen to cut wood or metal just. Previously, we’ve seen chisels to work with concrete, and now we have a chisel that can deal with workpieces made of bricks. Namely, brick chisels.

Brick chisels are also called bolsters chisels. Instead of brick sets, they are used to cut straight sides on bricks.

However, instead of bricks, brick chisels aren’t supposed to be used with any other material. Because once you do so, these chisels will lose up their sharpness.

Brick Chisel Uses

- To create sides and surfaces in bricks and walls made of blocks.

#16. Slick chisels

We listed and described paring chisels in this list. And slick chisels are just the oversized version of them. One quick way to recognize a slick chisel is its baseball bat-shaped handle, which comes to be super comfy to grip and work with.

However, the size of these chisels is large enough, and that’s why it’s mostly used for jobs like paring off thin slivers of wood from a particular log or wooden workpiece.

To deal with such kinds of jobs, the blade of this chisel is made to be broad and straight. And the cutting edge also comes to be of wide angles at 25 degrees.

Slick Chisel Uses

- In jobs like paring off thin wood slivers from wooden workpieces.[/su_list]

#17. Socket chisels

Wood chisels have quite some variations among themselves based on the manner through which the blade connects the handle. And one of these kinds is a socket chisel.

In a socket chisel, the connection between the blade and the handle is of ‘socket’ type. Which is better and stronger than many other connections like what we have in tang chisels?

One of the best things about socket chisels is, the handles are too good compared to other similar chisels like tang chisels. As the blade seats on the handle’s cone, it can take a lot of beating and pressure.

Stanley made some excellent quality socket chisels. We have recently reviewed their sweetheart socket chisels.

Socket Chisel Uses

- For heavy woodworks, especially when it has to go through heavy beatings.

#18. Firmer chisels

Firmer chisels had evolved in size and functionalities over the years. Earlier, we know firmer chisels as they made of solid steel and laminated/coated with iron.

In recent years, firmer chisels are likely to be manufactured from solid steel construction. The blade became quite flat along with square-sized edges.

From both constriction and design, firmer chisels known to be the oldest type of chisel, and that's what made them unique and extraordinary.

Firmer Chisel Uses

- For heavy woodworking especially, firmer chisels are used massively.

#19. Round chisels

Round or half-rounded chisels come with a curved cutting edge. Then it requires making narrow channels through the surface you're working with, you may need a round or half-round chisel.

Especially, metalwork requires many applications like this. As the use varies a lot based on workload, they come within some tip size, length, hex, etc.

No matter whichever size it is, the material is always steel. And the price of these materials is also quite less.

Round Chisel Uses

- To create narrow channels through metals.

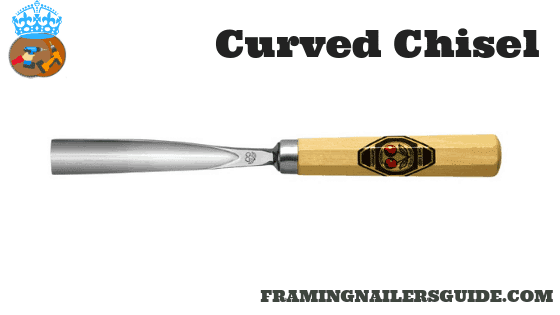

#20. Curved chisels

A curved chisel can be of two types- ones with a curved blade but straight gouge. And another is ones that have a straight blade but curved gouge.

Chisels having a U-shaped cutting edge can vary in depth and degree. But all of them are capable of removing more significant pieces of sticks. Also, they are widely used to give complex shapes to wooden works.

Curved Chisel Uses

- To cut larger stocks while woodworking.

- To provide shapes to complicated wooden structures.

#21. Dovetail chisels

Dovetail joints are quite common when it comes to professional plumbing or woodworking. And to give the woodworkers a hand in this we got dovetail chisels.

To help in finishing the dovetail joints, they usually come with a long and thin blade, which has beveled edges along with it. The cutting angle can lie between 20 to 30 degrees with the honed cutting edge.

It has many regular uses. But particular use of them can be to sharpen up the edges which interlocked among them. Also, as it has a thin and long blade, it can clean out edges that are interlocked.

Dovetail Chisel Uses

- For finishing dovetail joints.

- For sharpening or cleaning interlocked surfaces.

#22. Flat chisels

Flat chisels are the most widely used and familiar type of chisels. They have a straight and uniformly thick blade on a wooden base or handle. The structure is quite simple, but it can take loads of pressure and hammerings.

To do simple jobs like cutting bars and rods, or to reduce an area of a surface, or cutting sheet metals, flat chisels are in use across the world. Any works that are too thick or hard to do with usual woodworking tools like tin snips are done using flat chisels.

Flat Chisel Uses

- Cutting rods and bars.

- Reducing surface area from metals.

- Cutting sheet metals.

#23. Small chisels

There are many variations of chisels regarding size and functionality. And as long as the size is concerned, the length of both handle and blade can differ a lot. Based on how much space you have to move the chisel, or how small the workpiece is, you need to choose the size.

However, small chisels are those who have a lower blade in length, with a shorter handle as well. For work, where there is not ample space to move the handle, small chisels are used.

Small Chisel Uses

- To machine those kinds of jobs, where there is not enough space to move the handle.

#24. V chisels

When there is a V-groove in the blade of a chisel, we call it a V chisel. Also, some woodworkers claim that- when they need to use anything like a V-chisel, they took two V-tools together and made one V-chisel.

However, V chisel is also available in one piece, and that's what we're talking about here. When you have to cut edge and create a V-groove across the job, that's when you need a V chisel.

V Chisel Uses

- To create V-groove across the job.

#25. Bolster chisels

Bolster chisels are also known as brick bolsters, and the only use of them is on bricks.

Brick bolster chisels are not as sharp as other type of chisel, but they are used to break bricks primarily. And this doesn't need sharp edges, as you know.

Bolster Chisel Uses

- To break bricks and concrete-made workpieces.

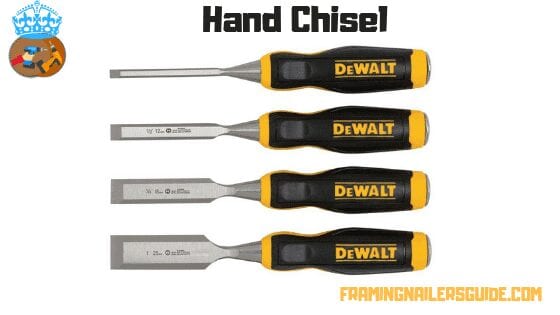

#26. Hand chisel

A while back, we learned about power chisels, where there is a motor provided to provide the cutting power. And the hand is everything that's not a power chisel.

As the relationship between hand tools and power tools, the difference between hand chisels and power chisels is only about power.

Hand Chisel Uses

- To provide smooth cuts, breaks, smoothening, or sharpening on various surfaces.

#27. Steel chisels

One of the most excellent reasons for using a steel chisel is its durability and ability to undergo heavy workloads. They can even stand mallets and hammer strikes. So, plumbers and woodworkers use to use it at outdoor work sites.

Moving forward, let's see the sizes that they are available in. These chisels are available in multiple sizes such as half inches, quarter inches, and larger quantities of a three-quarter-inch and one-inch. However, these sizing's were about the width of the cutting edge.

However, if your concern is about precision-based works; a steel chisel may not be the right option for you.

Steel Chisel Uses

- Using at working sites like construction works.

#28. Japanese wood chisels

Although we're calling them Japanese wood chisels, they made of wood along with two types of metal. The bottom handle of the chisel is wooden, like most of the chisels out there. But for the metal part, there are two types of metals.

One is the soft, white steel-made middle part of the chisel, and another is relatively hard, strong, and forged Carbon steel. Such materialistic property helps it to maintain a keep cutting edge.

On another note, the grain of Japanese chisels is one of the best of them all.

Japanese wood chisels Use

- For cutting jobs in hand works as paring.

#29. Bevel edge chisels

Bevel edge bench chisels are neither so long or too short in size. But these are some of the most commonly found chisels in any cabinet shop.

The edge is pretty good, and easy to sharpen up as well. The backside of the chisel should be hollow or sharp to sharpen easily. And on both sides, there should be bevels so that they can provide maximum access to any dovetails.

Another fine properly of them is they fit pretty well within the hands. So, it super-comfortable to use.

Bevel edge chisel Uses

- Commonly used for cutting and sharpening works in any cabinet shops.

In Conclusion

Hey, pat your back! You've just gone through 29 of the different types of chisels, and their uses. Although there are some more minor variations regarding design, material, and applications, this list is the basis of all of them. Once you have a firm idea on this list, you're good enough to go!